All rights reserved. Copyright Blue Rhino Industries of America 2023

PLC Touch Screen

“the old way” with mechanical

components

model

examples

made in

Arizona

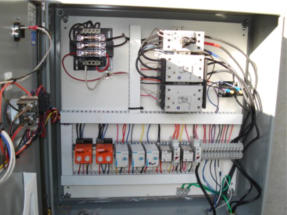

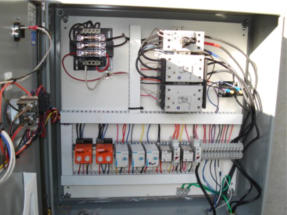

Control Panel

480-720-6236

All Blue Rhino Auger Compactors utilize an advanced computerized Compactor Control Panel,

which includes a Variable Frequency Drive (VFD) and a PLC touch screen interface. The VFD

provides numerous benefits, replacing mechanical starters, transformers, relays, timers and

fuses. These mechanical components have long been the cause of repair service calls,

expenses and equipment down-time. Our VFD is highly adjustable and reliable. One great

feature of our VFD system is the inclusion of a “soft start”. This feature lets our Auger

Compactor start at less than full-power initially and then quickly ramp-up to full power. This

method reduces strain on Auger Compactor driveline components, as well as your buildings

electrical supply. In some states “soft start” is beginning to be required by local authorities, to

reduce power spikes, due to poor power grids and supply.

Auger Compactor

Our touch screen PLC is where users will operate the Auger Compactor. The screen features

a start / forward button, reverse, stop and a reset button. The face of the control box will

still include the required mechanical emergency-stop push-button and keyed power switch, but

all other standard functions are performed on the PLC screen. The PLC screen displays a power

graph, indicating how hard the Auger Compactor is working, and how near to full the container

is. Through this interface, users have access to make limited adjustments, such as auger run-

time, without opening the control panel door. The PLC screen will also display warnings and

fault-codes, in the event of an error, as well as maintenance reminders, such as greasing the

bearing.

Auger Compactor

Blue Rhino Auger Compactor

All rights reserved. Copyright Blue Rhino

Industries of America 2023

model

examples

Control Panel

All Blue Rhino Auger Compactors utilize an advanced computerized

Compactor Control Panel, which includes a Variable Frequency Drive

(VFD) and a PLC touch screen interface. The VFD provides

numerous benefits, replacing mechanical starters, transformers,

relays, timers and fuses. These mechanical components have long

been the cause of repair service calls, expenses and equipment

down-time. Our VFD is highly adjustable and reliable. One great

feature of our VFD system is the inclusion of a “soft start”. This

feature lets our Auger Compactor start at less than full-power initially

and then quickly ramp-up to full power. This method reduces strain

on Auger Compactor driveline components, as well as your buildings

electrical supply. In some states “soft start” is beginning to be

required by local authorities, to reduce power spikes, due to poor

power grids and supply.

Auger Compactor

Our touch screen PLC is where users will operate the Auger

Compactor. The screen features a start / forward button, reverse,

stop and a reset button. The face of the control box will still include

the required mechanical emergency-stop push-button and keyed

power switch, but all other standard functions are performed on the

PLC screen. The PLC screen displays a power graph, indicating how

hard the Auger Compactor is working, and how near to full the

container is. Through this interface, users have access to make

limited adjustments, such as auger run-time, without opening the

control panel door. The PLC screen will also display warnings and

fault-codes, in the event of an error, as well as maintenance

reminders, such as greasing the bearing.

Blue Rhino Auger Compactor

PLC Touch Screen

“the old way” with mechanical

components